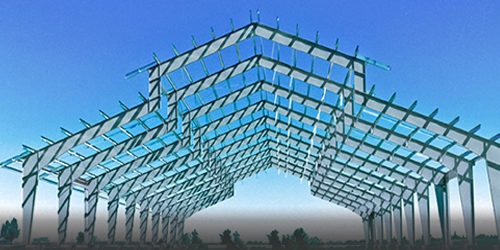

Efficient Setup Practices for Steel Buildings: Enhancing Your Building Refine

In the realm of construction, performance is a cornerstone of success. The process can be considerably structured by carrying out effective setup practices when it comes to putting up steel structures. From careful planning to the usage of pre-engineered components, each step plays an important duty in expediting the construction timeline. Nonetheless, the crucial lies not only in rate yet likewise in precision and top quality. By delving into the world of sophisticated installation strategies and making certain rigid high quality control measures, the possibility for enhancing the whole building and construction process comes to be not simply a possibility but a practical truth.

Planning for Effectiveness

When aiming to make the most of performance in steel building setup, meticulous preparation is important. Appropriate preparation sets the foundation for a smooth and orderly building and construction procedure, ultimately saving time and sources. The first action in planning for effectiveness is performing a comprehensive website evaluation. This evaluation helps identify any type of prospective barriers or obstacles that may develop throughout the setup procedure, enabling preemptive services to be developed. steel buildings.

Moreover, efficient communication among all stakeholders is paramount throughout the planning phase. Normal meetings and updates aid keep everybody on the exact same page, lessen misunderstandings, and promote a joint working setting - steel buildings. By investing effort and time right into careful preparation, steel building setup can be executed with accuracy and performance

Using Pre-Engineered Elements

Efficient steel structure installment techniques can be better improved by leveraging the use of pre-engineered parts. Pre-engineered components are created and made off-site to precise specs, ensuring compatibility and simplicity of setting up during the building process. By including pre-engineered parts such as beams, panels, columns, and trusses, builders can improve the setup procedure, lower on-site labor requirements, and reduce building waste.

One secret benefit of using pre-engineered elements is the considerable time savings they offer. Since these elements are produced in a controlled atmosphere, they come to the building website prepared for effective and fast setup. This not just increases the general building timeline however likewise helps to reduce project delays and linked expenses.

Moreover, pre-engineered elements are engineered for optimal efficiency and architectural honesty, making certain the long-lasting durability and security of the steel structure. By making use of these standard elements, contractors can achieve regular high quality across different tasks while additionally gaining from expense savings connected with minimized material waste and labor expenditures.

Maximizing Building Sequencing

To make best use of performance and effectiveness in steel building installation, critical optimization of building sequencing is critical. By carefully intending the order in which tasks are executed, building and construction teams can decrease downtime, reduce product handling, and simplify the total building procedure. One essential aspect of optimizing building sequencing is to prioritize essential path tasks that directly effect task timelines. This includes recognizing tasks that hinge on each various other and making sure that they are completed in the most reliable order to avoid delays. In addition, grouping similar jobs together can help minimize configuration and teardown time in between different tasks.

Carrying Out Advanced Installment Techniques

Carrying out innovative installment techniques enhances the efficiency and high quality of steel structure construction tasks. By incorporating cutting-edge techniques such as computer-aided layout (CAD) for accurate planning, prefabrication of elements off-site, and use of innovative equipment like robot welders, building and construction groups can significantly streamline the installation process. CAD software enables for in-depth 3D modeling, helping in the visualization of the final structure and guaranteeing accurate component measurements for a perfect fit throughout setting up. Prefabrication lowers on-site labor demands and building and construction time by making structure aspects in a controlled environment, reducing errors and rework. Making use of robot welders raises the rate and accuracy of welding tasks, boosting the total architectural stability of the steel building. Furthermore, applying innovative methods promotes safety and security by lowering hands-on labor requirements and possible office threats. By accepting development in installment methods, construction tasks can be completed faster, with greater quality outcomes, and go to my blog within budget plan constraints.

Making Sure Quality Assurance

Structure upon the application of advanced installment techniques, maintaining stringent top quality control actions is critical in making certain the architectural integrity and integrity of steel building projects. Quality control begins with the selection of high-quality materials that satisfy industry criteria and specs. Regular examinations throughout the building and construction procedure assistance determine any type of discrepancies from the style or potential problems that can endanger the structure's toughness.

Documents is an important element of quality assurance, making certain that all actions in the installment procedure adhere to the authorized laws and strategies. This consists of recording assessments, product accreditations, and any type of adjustments made during construction. Implementing a clear communication method amongst group members and subcontractors helps streamline the quality assurance procedure and resolve any kind of worries immediately.

Verdict

Finally, embracing reliable installation methods for steel structures is essential for enhancing the building and construction process. By thoroughly preparing, making use of pre-engineered parts, optimizing sequencing, executing sophisticated strategies, and ensuring quality assurance, building and construction tasks can more info here be finished quicker and properly. These techniques not just save time and sources however additionally contribute to the total success of the task. It is important to prioritize efficiency in order to optimize productivity and attain effective end results in steel structure construction.

To maximize performance and effectiveness in steel building installation, strategic optimization of building and construction sequencing is extremely important. Generally, by enhancing construction sequencing, steel structure setup can be completed more successfully, saving time and costs in the procedure.

Executing advanced installment methods enhances the performance and high quality of steel building construction tasks. By focusing on quality control throughout the installment process, building groups can provide steel buildings that are not just effective but additionally long lasting and dependable.

In final click resources thought, adopting reliable setup techniques for steel buildings is vital for streamlining the building and construction process.

Comments on “Top-Quality Steel Buildings: Resilient and Versatile Structures for Any Type Of Objective”